Taking into consideration climate and other conditions existing in the Kyrgyz Republic and CIS countries it is recommended to implement the following types of biogas plants.

Biogas plant with manual feed without agitation device and heating of substrate

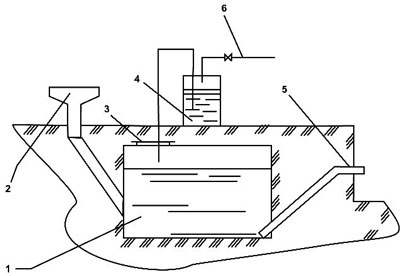

Simplest biogas plant (Figure 28) is intended for small farmer households. Digester volume of 1 – 10 m3 is adequate for fermentation of 50 – 200 kg of manure daily.

Plant contains minimum of construction parts necessary for digestion process and production of fertilizer and biogas: digester, mixing tank, equipment for collection and use of biogas, equipment for discharging digested substrate.

Such plants can be used in south regions of Kyrgyzstan without heating and agitation under psychophilic temperatures from 5ºС to 20С. Generated biogas is used directly in household appliances.

Fermented mass is discharged through outlet pipe at the moment of loading new substrate portion or due to growing biogas pressure in the digester. Discharged biofertilizer is received in temporary storage tank with volume no less of that of digester. Simplest biogas plant can be build by any farmer. Table contains specification and cost estimate of materials that are needed for it’s construction.

Work sequence for building simplest biogas plant

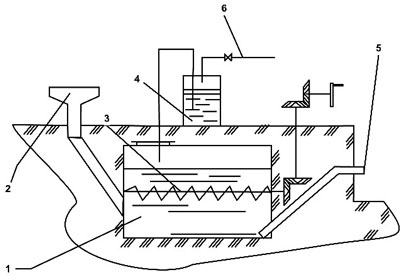

Figure 29. Diagram of a biogas plant with manual feed and agitation of substrate

1 – digester; 2 – mixing tank; 3 – agitation device;

4 – water trap; 5 – outlet pipe; 6 – biogas collection.

When building simplest biogas plant it is recommended to stick to following sequence of actions: after determining daily quantity of manure produced by the farm animals and choice of needed digester volume the location of biogas plant should be determined and all necessary material prepared. After that inlet and outlet pipes are mounted and foundation pit for biogas plant should be prepared.

After installing digester into the pit mounting of mixing pit and gas pipes is carried out, after which hatch though which technical maintenance and repair works can be carried out is installed. After this it is necessary to check impermeability of the digester, painting and insulation of the plant. The plant is ready for startup!

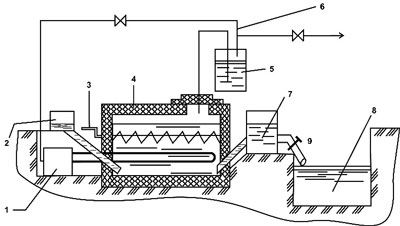

Figure 30. Diagram of a biogas plant with manual feed, agitation and heating of substrate

1 – water boiler; 2 – mixing tank; 3 –agitation device; 4 – digester;

5 – water trap; 6 – biogas collection; 7 – fertilizer tank; 8 – fertilizer storage;

9 – outlet pipe.

Biogas plant with manual feed and agitation of substrate

Construction of the biogas plant with manual feed and agitation of substrate (Figure 29) does not require large financial expenses.

It is intended for small farms. Digester volume of 1 to 10 m3 is calculated for digestion of 50 – 200 kg of manure daily. For increasing the efficiency of biogas plant operation manual agitation device is installed into digester.

Biogas plant with manual feed, agitation and heating of substrate

For a more intensive and stable digestion process heating system is added to digester (Figure 30).

Plant is able to operate in mesophilic and thermophilic temperature ranges. Digester is heated with water boiler that works on generated biogas. The rest of the biogas is used directly in household appliances.

Digested slurry is stored in special tank until it is applied to soil.

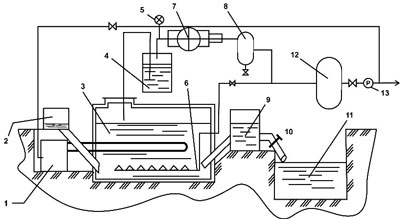

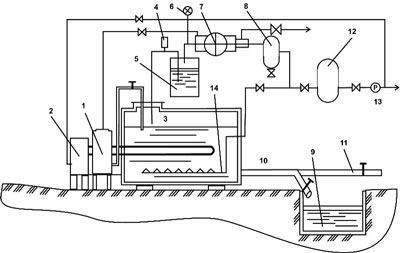

Figure 31. Diagram of a biogas plant with manual feed, gas holder, pneumatic agitation and heating of substrate

1 – water boiler; 2 – loading tank; 3 – digester; 4 – water trap; 5 – electric manometer; 6 – agitation device; 7 – compressor; 8 – receiver; 9 – discharge tank;

10 – substrate discharge; 11 – biofertilizer storage; 12 – gas holder; 13 – gas reducer.

Biogas plant with manual feed, gas holder, pneumatic agitation and heating of substrate

Simple biogas plant with manual feed is equipped with automatic biogas pumping device and a gas holder for its storage (Figure 31).

Agitation of substrate in digester is carried out using pneumatic method with biogas.

This biogas plant can work under any temperature ranges.

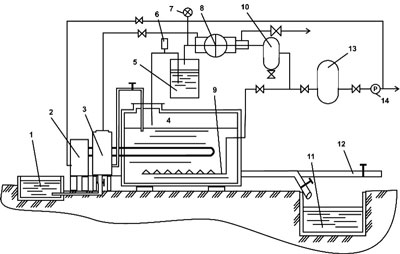

Figure 32. Diagram of a biogas plant with gas holder,

manual preparation, pneumatic feed and agitation of

substrate and with heating of substrate

1 – substrate loading tank; 2 – water boiler; 3 – digester; 4 – safety valve;

5 – water trap; 6 – electric manometer; 7 – compressor; 8 – receiver;

9 – biofertilizer storage; 10 – substrate discharge;

11 – discharge pipe branch for vehicles; 12 – gas holder; 13 – gas reducer; 14 – agitation device.

Biogas plant with gas holder, manual preparation, pneumatic feed and agitation of substrate and with heating of substrate

This plant (Figure 32) is intended for use of small and medium-sized farms and is capable of digesting 0,3 to 1,5 ton of substrate per day. Digester volumes range from 5 to 25 m3.

Loading and agitation of substrate are automated and are carried out pneumatically.

Substrate is heated with help of heat exchanger with water boiler working on biogas. Outlet pipe has a branching for collecting biofertilizer in storage tank or loading vehicles for transferring it to fields.

Construction of this biogas plant envisages manual preparation and pneumatic load of substrate into digester, a part of generated biogas goes to heat up the substrate. Agitation is carried out by biogas. Gas collection is automated and biogas can be stored in gas holder. Plant can operate in any digestion temperature range.

Figure 33. Diagram of farmer’s biogas plant with gas holder, automated preparation, pneumatic feed and agitation of substrate and heating of substrate

1 – substrate mixing tank; 2 – water boiler; 3 –loading tank;

4 – digester; 5 – water trap; 6 – safety valve;

7 – electric manometer; 8 – compressor; 9 – biogas agitation device;

10 – receiver; 11 – biofertilizer storage;

12 – outlet pipe branch for loading substrate onto vehicles;

13 – gas holder; 14 – gas reducer.

Biogas plant with gas holder, automated preparation, pneumatic feed and agitation of substrate and heating of substrate

Special characteristic of this plant (Figure 33) intended for use in middle and large-sized farms is availability of special substrate preparation tank from which it is moved with the help of compressor into loading tank and then with the help of compressed biogas into digester.

For heating system part of generated biogas is used. Plant is supplied with automated biogas collection system and a gas holder for its storage.

Presence of a heating system allows plant to operate in all digesting regimes.