Agitation goals

Agitation of the fermented mass in digester increases efficiency of biogas plant operation and provides for:

• removal of the metabolites produced by the methanogens (gas)

• mixing of fresh substrate and bacterial population (inoculation)

• preclusion of scum formation and sedimentation

• avoidance of pronounced temperature gradients within the digester

• provision of a uniform bacterial population density

• prevention of the formation of dead spaces that would reduce the effective digester volume.

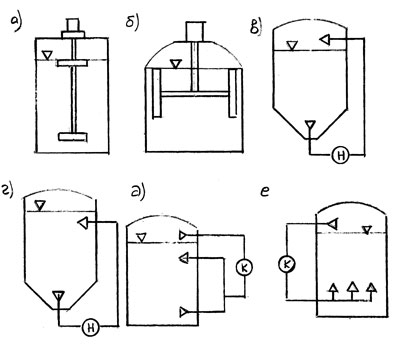

Figure 24. Agitation systems for vertical digestersа,б – mechanical mixing; в,г – pump agitation;

д – biogas and liquid mixing; е – biogas mixing.

Agitation methods

Agitation of substrate ca be carried out using the following main methods: Automated stirring, with biogas and by pumping of substrate from the upper digester zone into the lower. Automated stirrers agitate substrate with screw, fane or slats and they can be operated manually or from an engine.

Automated agitation

Automated agitation with the help of mechanical paddle rotors are predominantly used in horizontal steel vessels. A horizontal shaft in hardwood bearings runs through the whole vessel. Attached are paddles or loopshaped pipes. By turning the shaft the vessel contents are mixed, the swimming layer is broken up and sediments are pushed towards a drainage opening.

Mechanical mixers with manual operation are the most common and simple in use. They are used in small-sized digesters with low biogas yield and consist of a horizontal or vertical shaft installed parallel to main axes. The shaft is equipped with paddles of other elements with helical surface that provide the movement of the biomass reach with methane bacteria from the outlet to inlet. This allows to speed up the methane production and shorten the retention time.

Hydraulic mixing

With a strong pump the whole substrate can be put in motion, provided the intake and outlet of

the pump are placed in a way that corresponds with the digester shape. These pumps are often

placed in a central position to cater for other tasks.

Pneumatic agitation

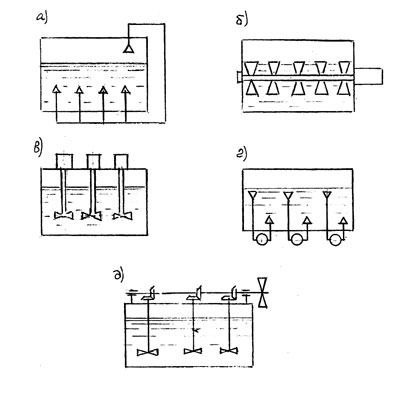

Figure 25. Agitation equipment for horizontal digestersа – biogas agitation; б – mechanical fans;

в – mechanical mixer with electrical engine;

г – pump mixing;

д – mechanical mixing from wind motor.

Pneumatic agitation is carried out by installing piping system with gas-jets at the bottom of the digester and pumping biogas through this system. The raising biogas bubbles provide a gentle mixing of the substrate. The main problem with these systems is slurry entering into the piping system. This can be avoided by fixing pieces of elastic hosepipe with stainless steel hose coupling to the jets.

Pneumatic mixing by injecting biogas should be used if the formation of swimming layers

is not a prevailing problem.

Frequency of substrate agitation

Agitation can be constant of periodical depending the digester operation regime. Optimal frequency considerably decreases digestion time and prevents scum formation.

Partial agitation of substrate is happening naturally through biogas generation, temperature movement and movement of substrate due to new loaded portions, but this agitation is not sufficient.

Agitation has to be regular. Under rare agitation substrate divides into layers and scum id formed on the top of it, decreasing the efficiency of biogas production. Correctly agitated substrate can produce 50% more of biogas.

If agitation is excessive, the bacteria have “no time to eat”. Additionally it can lead to unloading of not fully fermented substrate. The ideal is gentle but intensive stirring about every 4 – 6 hours.